Control of the correctness of lightning protection and electrical installations

Article 18 of the Law on Fire Protection (Official Gazette of SRS No. 37/88), and Article 15 and 16 of the Rulebook on technical norms for the protection of buildings against atmospheric discharge.

Control and measurement of the grounding resistance of the lightning protection installation for the protection of buildings against atmospheric discharge is performed once a year.

Maintenance of lightning protection installation

- 1. The maintenance of the lightning protection installation must be carried out by an electrical assembly service or a company that has the appropriate professional service, in accordance with the maintenance program defined by the project of the lightning protection installation.

- 2. Maintenance of lightning arrester installations is important in order to maintain the appropriate level of protection and efficiency of lightning arrester installations, because their components are subject to loss (partial and complete) of their properties over the years of exploitation due to corrosion, atmospheric influences, damage caused by the effects of time, mechanical damage and damage due to impact thunder. 3. A lightning protection installation maintenance program must be defined for the entire lightning protection installation, and must contain a list of common items that serve as a check list to enable comparison of inspection results with previous results. 4. The lightning protection installation maintenance program includes:

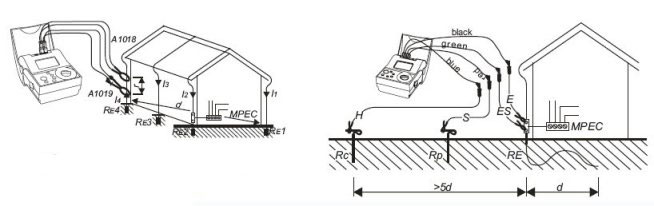

- a. checking all conductors in the lightning protection installation and system components; b. checking the tightness of all clamps and connectors; c. checking electrical continuity in the installation; d. measurement of resistance to the ground in the grounding system;

- e. checking the surge protection device; f. checking whether the effect of the lightning protection installation has changed after the reconstruction of the building or its installations.

- 5. Reports on all maintenance procedures, undertaken measures that need to be taken, are the basis for assessing the quality of the lightning protection installation and its components and must be kept together with the lightning protection installation project.

- 1. The control of the lightning arrester installation upon completion of the works is carried out by an authorized person of the organization registered for the technical acceptance of lightning arrester installations and an authorized person from the jurisdiction of the Secretariat of Internal Affairs, Directorate for Fire Protection and Preventive Technical Protection, based on the design of the lightning arrester installation and the inspection report.

- 2. Then it is established: that the lightning protection installation corresponds to the project; that all components of the lightning arrester installation are in technically correct condition and that they provide the applied and specified functions; that there is no effect of corrosion on the elements of the lightning protection installation; that all subsequently added parts of the building installed in the protected area are protected by potential equalization or "extension" of the lightning arrester installation. 3. Regular control of the lightning rod installation must be carried out on the basis of the "control program" which is an integral part of the lightning rod installation project. 4. All lightning protection installations must be controlled in the following cases:

- a. during the installation of lightning protection for parts that are inaccessible after the completion of the building; after completing the complete installation.

- 5. The interval between inspections of lightning protection installations is determined based on the following factors:

- a. type of object or protective zone, especially with regard to the consequences of any damage; b. level of protection;

c. local environment (corrosion problems);

d. applied materials for individual components of the installation;

- e. types of soil ...

- a. whether the system is in good condition; b. whether there are loose connections and breaks in the conductors of the lightning protection installation and connections; c. that the specified part of the system is not weakened by corrosion; d. that all connections with grounding are undamaged;

- e. that all conductors and system components are well received and protected from accidental mechanical damage; f. that the surge protection devices are not damaged; Mr. that the potential is properly equalized for each new installation or construction that is added to the interior of the building; h. that the conductors for potential equalization and the conductors inside the object are undamaged

- a. carry out continuity tests, especially for those parts of the lightning arrester installation that are not visible for control and at the beginning of the execution; b. perform tests of the resistance of the spread of the grounding system and its individual grounding devices and the results are compared with the previous or original and in case of differences that are not acceptable, measures are taken for improvement; c. controlled and tested equipotential bonding conductors, joints, shields, cable routes and surge protection devices.

Testing of electrical installations

- 1. equalization of potential,

- 2. checking the electrical resistance of the insulation of the electrical installation, 3. checking the electrical resistance of floors and walls, 4. checking the efficiency of the protection system by automatically turning off the power supply, i

- 5. verification of supplementary potential equalization.